Injection Mold Business KOMO HIPRO

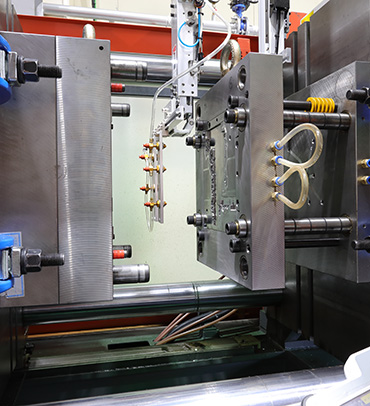

Respond from the Beginning (Test Production)to Mass Production

We have a comprehensive manufacturing system that spans from initial attempts

to produce electronic components and automotive parts to mass production.

Sufficient test molding is a critical part of our mold production, and fine adjustments

of the mold prior to mass production are done perfectly.

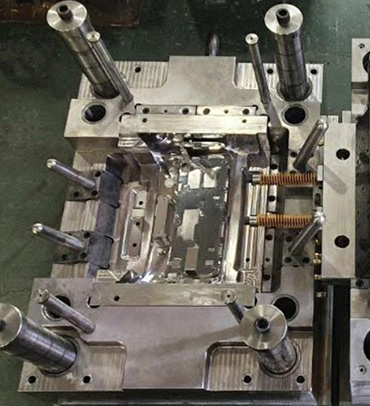

Metal Mold Business KOMO HIPRO

Efficient Performance through Automated Equipment

With a focus on improving work efficiency and preventing human errors,

we have introduced the “NC BRAIN” program to check work quality through pre-simulation.

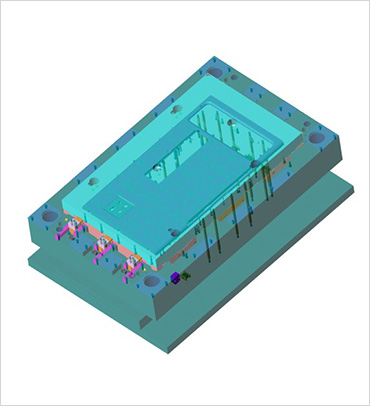

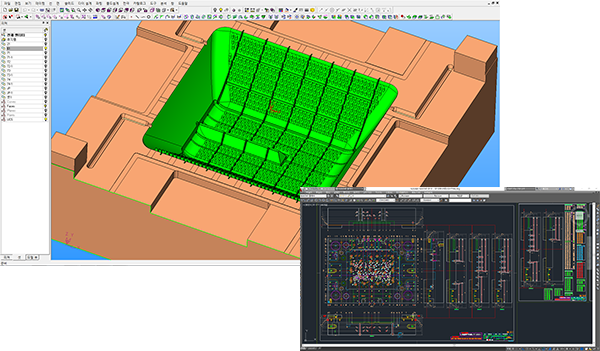

Mold Design through 3D CAD/CAM

The introduction of 3D CAD/CAM systems "NX" and "POWER MILL" has increased the efficiency of our mold design processes.

Connector Business KOMO HIPRO